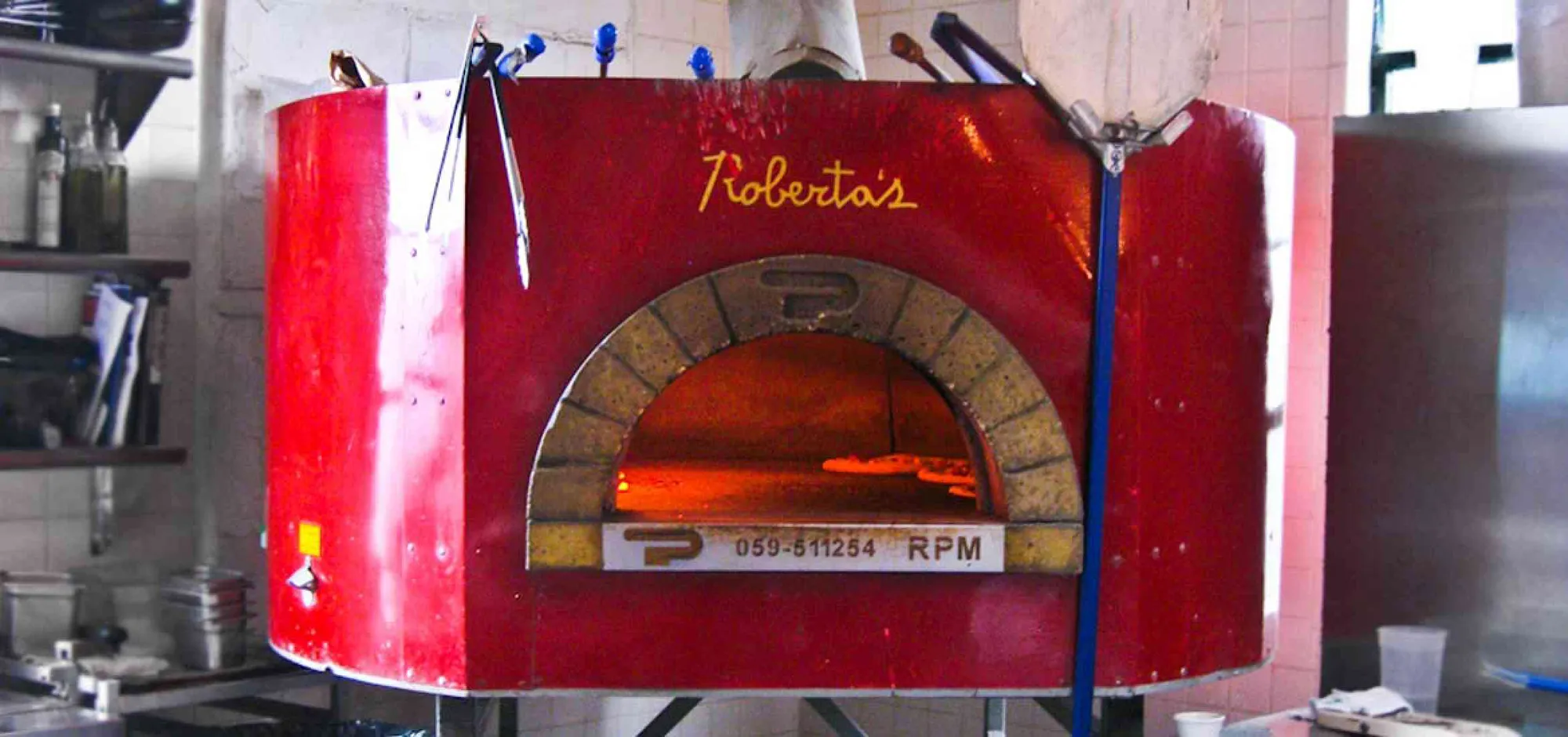

RPM 120

The RPM 120 model is one of our most appreciated gas ovens, renowned worldwide for its quality. Compact dimensions, versatility, and responsiveness make it a product that combines tradition with technology to deliver excellent performance.

The hearth – made from a single refractory block – guarantees even cooking and easy temperature maintenance. The standard racing-red sheet metal gives it a unique appearance, while the color itself is fully customizable. Finally, this oven features an electronic temperature control and stainless steel protection for use with wood, making it a versatile and easy-to-use product.

Contact us to benefit from craftsmanship and handmade production made in Italy. With over 50 years of experience, we have the ability to collaborate with clubs and restaurants worldwide.

Capacity

5/6 pizzas

Power

Gas

Hearth

Fixed

Vault

Domed

Lining

Standard red sheet metal, customizable with color as desired

Hearth thickness

7 cm

Included

Dual-torch burner with electronic temperature control. As a result of the stainless steel soot protection mounted on the burner, wood can also be used for cooking.

Optional

Combined wood/gas use